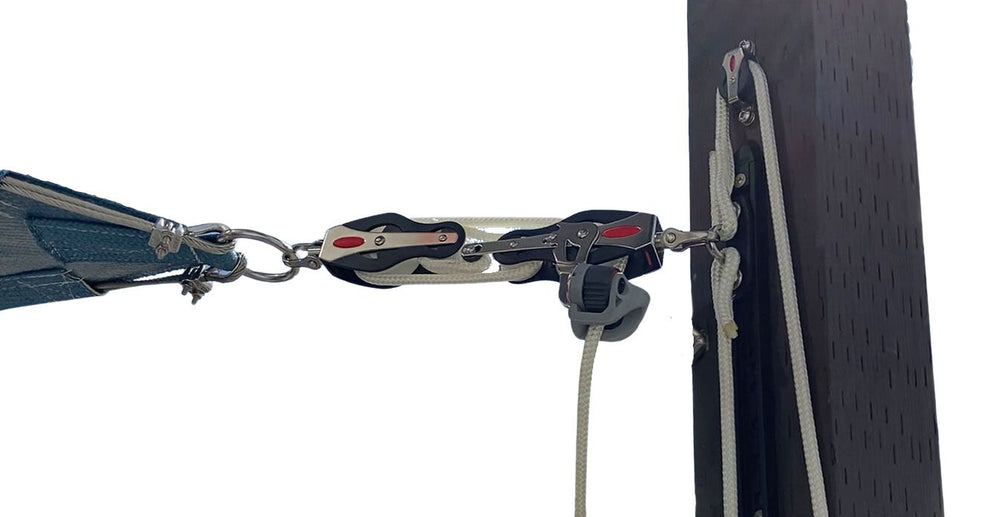

Tensioning & Attachment Hardware

Tensioning and Attachment Hardware are included with every Shade Sails Canada product.

This hardware is essential to ensure your Shade Sails Canada product tensions and performs as intended. Professionally installed during production, it is designed to last a lifetime, provided your shade sail is installed correctly.

Our Tensioning Hardware is also available for purchase if you’re looking for spare parts, working on a project, or need high-quality Marine Grade Stainless Steel components.

- 316 Marine Grade Stainless Steel

- High load rated

- Range of sizes available

- Hand-picked for exceptional design and durability

- Fits a wide range of installations

Frequently Asked Questions

"Tensioning Hardware" refers only to the Marine Grade Stainless Steel that we include with your Shade Sails Canada product in the production line. Turnbuckles, d-shackles, and perimeter cabling are all included with your product, but should you need spares or wish to purchase more of our high-quality hardware, you can certainly do so.

"Anchor Hardware" refers to the connection points on your structure or post. Shop Anchor Hardware here.

Stainless Steel hardware is highly resistant to corrosion and staining and can maintain its strength and durability at high temperatures. It is also non-magnetic and has a sleek, modern appearance. Additionally, Stainless Steel is easily recyclable, making it an environmentally friendly option for various applications.

A seized turnbuckle can be treated by using penetrating oil, such as the Turnbuckle Grease we provide with every product. Apply some Turnbuckle Grease or a penetrating lubricant to loosen the corrosion or rust that is causing the seizing. Once freed, apply additional grease to the turnbuckle thread and allow it to sit for a few minutes before re-tensioning. You can also try to use a wrench or pliers to gently turn the turnbuckle back and forth, applying pressure as needed. If the turnbuckle still does not turn, you may need to replace it.